Product (323)

- Hydraulic Oil cooler (15)

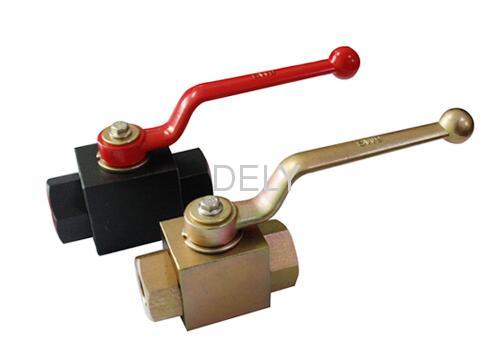

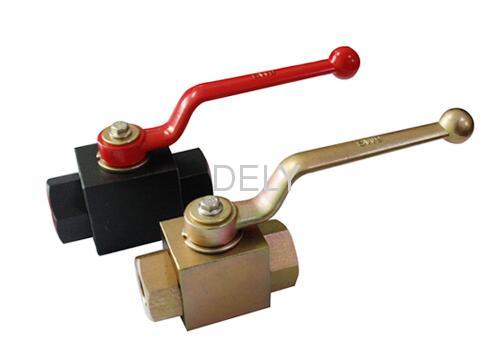

- Ball Valve (65)

- Quick Coupler (16)

- Pneumatic Cylinders (49)

- Air Filter Regulator (31)

- Solenoid Valve (40)

- Mechanical Valve (20)

- Pneumatic Fitting (39)

- Pneumatic Silencer (6)

- Pneumatic Component (8)

- pneumatic (31)

- Others (3)

Blog (21)

Company image (2)

News (2)

Certificates (4)

Credit Report

Products Index

Blog

What are the different types of end connections available for high-pressure ball valves?

- Threaded: High-pressure ball valves may have threaded end connections, such as NPT (National Pipe Thread) or BSPT (British Standard Pipe Taper) threads. These connections are suitable for smaller pipe sizes and lower-pressure applications.

- Socket Weld: Socket weld end connections have a socket-like recess into which the pipe is inserted and then welded for a secure connection. This type of end connection is commonly used for higher-pressure applications.

- Butt Weld: Butt weld end connections involve welding the valve directly to the pipe, creating a strong and leak-proof joint. Butt weld connections are suitable for high-pressure and high-temperature applications.

- Flanged: Flanged end connections have a raised face or flat face with bolt holes, allowing the valve to be bolted to the pipe flanges. Flanged connections are commonly used in larger pipe sizes and high-pressure applications.

- Clamp or Quick Connect: Some high-pressure ball valves feature clamp or quick connect end connections, which allow for easy installation and removal without the need for welding or threading.

It is important to select the appropriate end connection type based on the specific requirements of the application, ensuring compatibility with the piping system and maintaining the desired pressure rating and integrity.

Pre Page:

Are high-pressure ball valves suitable...

Next Page:

How often do high-pressure ball valves...