|

NINGBO DELY AUTOMATION Co.,Ltd.

|

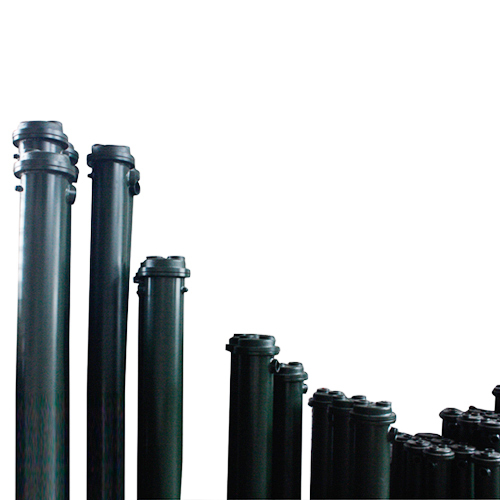

Coolers and Heat Exchangers

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

Hydraulic system, to lower the hydraulic oil temperature.

Product name:Coolers and Heat Exchangers

Model no.: GLC2-1.3,

GLC2-1.7,

GLC2-2.1,

GLC2-2.6,

GLC2-3.0,

GLC2-3.5,

material: finned copper tube

( 2 Series: there is 20pcs finned copper tubes inner. the thicknesss of tube: 0.8mm)

Using: Hydraulic System, you can use water oil cooler to cool the hydraulic medium( like hydraulic oil). this item, simple struction, easy to use, good result.

GLC series Calandria Water Oil Cooler

Product Introduction:

calandria oil cooler: used for cooler the medium (viscosity lubricator, hydraulic oil) for certain temperature

Model Code:

| Model | Heat exchange area(Square meter) | Pressure(MPa) | Temperature(℃) | Medium viscosity 10-6M2/S | Medium viscosity (L/min) | Oil/water flow scale | Heat exchange (Kcal/h) | weight(kg) | |||||

| Working pressure | Oil pressure drop | Water pressure | Working water temperature | Working oil temperature | Inlet oil temperature | Outlet oil temperature | |||||||

| GLC1-0.4 | 0.4 | 0.63 1 | ≤0.1 | ≤0.05 | 25-30 | ≤100 | 55 | ≤46 | 10-50 | 10-35 | 1:1 | 1300-3300 | 10 |

| -0.6 | 0.6 | 25-60 | 3300-5100 | 13 | |||||||||

| -0.8 | 0.8 | 35-60 | 3350-6500 | 15 | |||||||||

| -1 | 1 | 60-75 | 6100-7200 | 17 | |||||||||

| -1.2 | 1.2 | 60-85 | 6400-8400 | 19 | |||||||||

| GLC2-1.3 | 1.3 | 0.63 | ≤0.1 | ≤0.05 | 25-30 | ≤100 | 55 | ≤46 | 10-50 | 30-85 | 1:1 | 6400-11000 | 21 |

| -1.7 | 1.7 | 30-113 | 7400-17000 | 26 | |||||||||

| -2.1 | 2.1 | 30-113 | 9200-21500 | 29 | |||||||||

| -2.6 | 2.6 | 35-125 | 11300-26000 | 33 | |||||||||

| -3 | 3 | 35-125 | 12700-30000 | 37 | |||||||||

| -3.5 | 3.5 | 40-150 | 14500-34500 | 41 | |||||||||

| GLC3-4 | 4 | 0.63 1 | ≤0.1 | ≤0.05 | 25-30 | ≤100 | 55 | ≤46 | 10-50 | 34-170 | 1:1 | 14000-31000 | 57 |

| -5 | 5 | 35-190 | 17000-35000 | 70 | |||||||||

| -6 | 6 | 40-220 | 20000-45000 | 83 | |||||||||

| -7 | 7 | 45-240 | 24000-49500 | 90 | |||||||||

| -8 | 8 | 50-280 | 27000-56000 | 96 | |||||||||

| -9 | 9 | 50-290 | 31000-67000 | 105 | |||||||||

| -10 | 10 | 60-320 | 33590-69500 | 110 | |||||||||

| -11 | 11 | 60-350 | 37500-79000 | 118 | |||||||||

| GLC4-13 | 13 | 0.63 1 | ≤0.1 | ≤0.05 | 25-30 | ≤100 | 55 | ≤46 | 10-50 | 50-300 | 1:1 | 35000-70000 | 152 |

| -15 | 15 | 50-320 | 38000-75000 | 164 | |||||||||

| -17 | 17 | 60-350 | 42000-83000 | 175 | |||||||||

| -19 | 19 | 60-400 | 46000-89500 | 188 | |||||||||

| -21 | 21 | 70-430 | 50000-93000 | 200 | |||||||||

| -23 | 23 | 70-450 | 55000-99000 | 213 | |||||||||

| -25 | 25 | 80-480 | 60000-10200 | 225 | |||||||||

| -27 | 27 | 80-520 | 60000-12200 | 238 | |||||||||

| GLC5-30 | 30 | 0.63 1 1.6 | ≤0.1 | ≤0.05 | 25-30 | ≤100 | 55 | ≤46 | 10-50 | 150-650 | 1:1 | 8-15 | 255 |

| -34 | 34 | 150-700 | 8-17 | 280 | |||||||||

| -37 | 37 | 200-800 | 10-19 | 298 | |||||||||

| -41 | 41 | 200-850 | 10-21 | 322 | |||||||||

| -44 | 44 | 250-900 | 11-25 | 340 | |||||||||

| -47 | 47 | 250-950 | 11-27 | 357 | |||||||||

| -51 | 51 | 300-1000 | 13-30 | 380 | |||||||||

| -54 | 54 | 300-1100 | 13-33 | 398 | |||||||||

| GLC6-55 | 55 | 0.63 1 1.6 | ≤0.1 | ≤0.05 | 25-30 | ≤100 | 55 | ≤46 | 10-50 | 350-1150 | 1:1 | 15-35 | 418 |

| -60 | 60 | 350-1200 | 15-38 | 442 | |||||||||

| -65 | 65 | 400-1250 | 17-41 | 469 | |||||||||

| -70 | 70 | 400-1300 | 17-45 | 498 | |||||||||

| -75 | 75 | 500-1350 | 20-50 | 525 | |||||||||

| -80 | 80 | 500-1400 | 20-55 | 550 | |||||||||

| -85 | 85 | 600-1500 | 25-60 | 575 | |||||||||

| -90 | 90 | 600-1600 | 30-70 | 602 | |||||||||

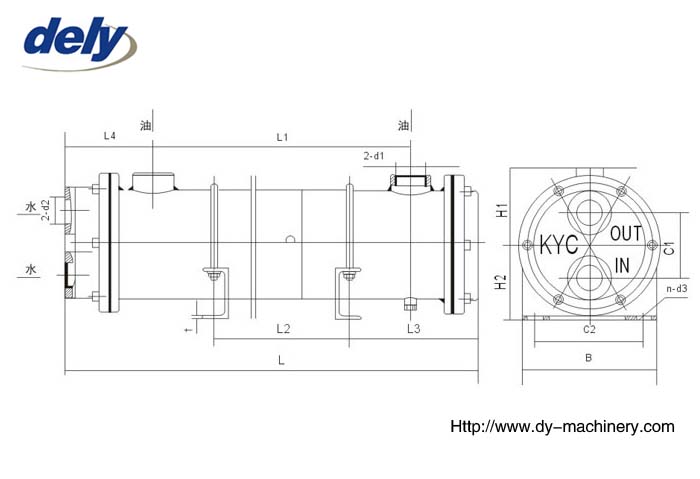

| Model | L | L1 | L2 | L3 | L4 | B | C1 | C2 | D | H1 | H2 | t | d1 | d2 | n-d3 |

| GLC1-0.4 | 383 | 240 | 145 | 116 | 75 | 132 | 48 | 102 | 83 | 68 | 74 | 2 | G1" | G3/4" | 4-∮9 |

| -0.6 | 548 | 405 | 310 | ||||||||||||

| -0.8 | 675 | 532 | 435 | ||||||||||||

| -1 | 808 | 665 | 570 | ||||||||||||

| -1.2 | 948 | 805 | 715 | ||||||||||||

| GLC2-1.3 | 542 | 374 | 225 | 153 | 90 | 170 | 78 | 138 | 121 | 87 | 96 | 2 | G1" | G1" | 4-∮11 |

| -1.7 | 668 | 500 | 350 | ||||||||||||

| -2.1 | 802 | 634 | 485 | ||||||||||||

| -2.6 | 944 | 776 | 630 | ||||||||||||

| -3 | 1094 | 926 | 780 | ||||||||||||

| -3.5 | 1252 | 1084 | 935 | ||||||||||||

| GLC3-4 | 815 | 570 | 380 | 203 | 136 | 210 | 100 | 170 | 168 | 109 | 117 | 2 | G11/2" | G11/4" | 4-∮15 |

| -5 | 965 | 720 | 530 | ||||||||||||

| -6 | 1115 | 870 | 680 | ||||||||||||

| -7 | 1285 | 1040 | 856 | ||||||||||||

| -8 | 1445 | 1200 | 1010 | G2" | G11/2" | ||||||||||

| -9 | 1605 | 1360 | 1170 | ||||||||||||

| -10 | 1775 | 1530 | 1340 | ||||||||||||

| -11 | 1955 | 1710 | 1520 | ||||||||||||

| GLC4-13 | 1270 | 985 | 745 | 248 | 156 | 270 | 130 | 220 | 219 | 137 | 150 | 3 | G2" | G2" | 4-∮19 |

| -15 | 1430 | 1145 | 705 | ||||||||||||

| -17 | 1590 | 1305 | 1065 | ||||||||||||

| -19 | 1760 | 1475 | 1235 | ||||||||||||

| -21 | 1940 | 1655 | 1415 | ||||||||||||

| -23 | 2110 | 1825 | 1585 | ||||||||||||

| -25 | 2290 | 2005 | 1765 | ||||||||||||

| -27 | 2460 | 2175 | 1935 | ||||||||||||

| GLC5-30 | 1870 | 1570 | 1320 | 260 | 165 | 330 | 168 | 270 | 273 | 168 | 198 | 9 | G2" | G21/2" | 4-∮23 |

| -34 | 2090 | 1790 | 1540 | ||||||||||||

| -37 | 2260 | 1960 | 1710 | ||||||||||||

| -41 | 2480 | 2180 | 1930 | ||||||||||||

| -44 | 2650 | 2350 | 2100 | ||||||||||||

| -47 | 2810 | 2510 | 2260 | ||||||||||||

| -51 | 3030 | 2730 | 2480 | ||||||||||||

| -54 | 3200 | 2900 | 2650 | ||||||||||||

| GLC6-55 | 2209 | 1860 | 1590 | 295 | 189 | 390 | 196 | 300 | 325 | 198 | 223 | 9 | G21/2" | G3" | 4-∮23 |

| -60 | 2389 | 2040 | 1770 | ||||||||||||

| -65 | 2569 | 2220 | 1950 | ||||||||||||

| -70 | 2749 | 2400 | 2130 | ||||||||||||

| -75 | 2929 | 2580 | 2310 | ||||||||||||

| -80 | 3109 | 2760 | 2490 | ||||||||||||

| -85 | 3289 | 2940 | 2670 | ||||||||||||

| -90 | 3469 | 3120 | 2850 |

An oil-water cooler is a device used to cool down oil that is being used in various industrial applications. It is commonly used in hydraulic systems, gearboxes, engines, and other machinery that generate heat during operation.

The cooler works by passing the hot oil through a series of tubes or plates, while cool water is circulated around these tubes or plates. This allows for the transfer of heat from the oil to the water, effectively cooling down the oil.

The main components of an oil-water cooler include:

Oil circuit: This is the path through which the hot oil flows. It typically consists of inlet and outlet connections, as well as internal passages or tubes that facilitate the flow of oil.

Water circuit: This is the path through which the cool water circulates. It includes inlet and outlet connections, as well as internal passages or tubes that allow the water to flow around the oil-carrying tubes or plates.

Heat exchange surface: This refers to the tubes or plates where the heat transfer occurs. These surfaces are designed to maximize the contact area between the hot oil and the cool water, enhancing the heat transfer efficiency.

Cooling medium: In the case of an oil-water cooler, the cooling medium is water. The water can be sourced from a cooling tower, chiller, or other water supply systems.

Control mechanisms: Some oil-water coolers may have control mechanisms to regulate the flow rate of both the oil and water, ensuring optimal cooling performance.

Improved efficiency: By cooling down the oil, an oil-water cooler helps maintain the optimal operating temperature of the machinery, which can improve overall efficiency and performance.

Extended equipment life: Cooling the oil helps prevent overheating and reduces the risk of damage to the machinery, leading to longer equipment life and reduced maintenance costs.

Temperature control: An oil-water cooler allows for precise temperature control of the oil, ensuring that it remains within the desired operating range.

Environmental benefits: Cooling the oil can help reduce energy consumption and minimize the environmental impact associated with excessive heat generation.

The benefits of using an oil-water cooler include:

Overall, an oil-water cooler is an essential component in many industrial applications, providing efficient cooling and temperature control for the oil used in various machinery and systems.

Company Profile:

Ningbo Dely Automation Co. ltd. specailly manufacturer and market hydraulic ball valve,hydraulic fitting,pneumatic control element,air source units,pneumatic execute element and pneumatic assistant element.We have passed ISO9001:2000 quality system authentication.With advanced technology and equipment,good quality,our products sale far to many countries.In order to meet more and more customer's requirements.