|

NINGBO DELY AUTOMATION Co.,Ltd.

|

QJH high carbon steel pressure globe stop valve

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

QJH Series High Pressure Globe Stop Valve,with resonable structure,reliable ability.Casting steel material and self-lubricating seal.

Product name:QJH high carbon steel pressure globe stop valve

Modle number:QJH-15F

Connection Type: B-Plate way ( QJH-10B, 15B, 20B, 25B, 32B, 40B )

NL-Femal thread ( QJH-10NL, 15NL, 20NL, 25NL, 32NL, 40NL )

WL-Male thread ( QJH-10WL, 15WL, 20WL, 25WL, 32WL, 40WL )

F-(Activity)round falnge way ( QJH-10F, 15F, 20F, 25F, 32F, 40F, 50F, 65F)

F1-Welded flange-type way (QJH-50F1, 65F1, 80F1)

QJH high carbon steel pressure globe stop valve

Introduction:

QJH Series High Pressure Globe Stop Valve,with resonable structure,reliable ability.Casting steel material and self-lubricating seal.The valve is anti-corruption.The material can be stinless steel also

Model Code:

1:Name code:QJ

2:Nominal Pressure:H-31.5MPa

3:Port Size:10~50mm

4:Connection Type:B-Plate way NL-Femal thread WL-Male thread

F-(Activity)round falnge way F1-Welded flange-type way

Overall Dimensions(mm)

| Model | L | B | C | L1 | L2 | L3 | L4 | L5 | L6 | H | N | 1 | 2 |

| QJH-10B | 80 | 54 | 40 | 60 | 45 | 11 | 12 | 127 | 33 | 38 | 62 | 7 | 10 |

| QJH-15B | 91 | 60 | 46 | 56 | 52 | 6 | 19 | 127 | 39 | 42 | 66 | 9 | 15 |

| QJH-20B | 108 | 70 | 54 | 70 | 60 | 8.5 | 21.5 | 184 | 46.7 | 50 | 70 | 11 | 20 |

| QJH-25B | 125 | 77 | 60 | 80 | 72 | 3 | 30 | 184 | 54.7 | 55 | 73 | 11 | 25 |

| QJH-32B | 161 | 100 | 72 | 120 | 99 | 14 | 23 | 215 | 74.3 | 75 | 104 | 13 | 32 |

| QJH-40B | 187 | 122 | 90 | 150 | 112 | 23 | 20 | 215 | 86.8 | 90 | 129 | 17 | 40 |

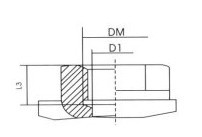

| Model | DM | L | D1 | D2 | L3 | L4 | H | B |

| QJH-6WL | M16X1.5 | 70 | 6 | 11 | 12 | 1.28 | 27 | 24 |

| QJH-10WL | M22X1.5 | 86 | 10 | 16 | 14 | 1.97 | 37 | 34 |

| QJH-15WL | M30X1.5 | 96 | 15 | 25 | 16 | 1.97 | 40 | 35 |

| QJH-20WL | M36X2 | 114 | 18 | 30 | 18 | 1.97 | 55 | 48 |

| QJH-25WL | M42X2 | 122 | 22 | 35 | 20 | 1.97 | 61 | 58 |

| QJH-32WL | M52X2 | 145 | 30 | 40 | 22 | 1.97 | 72 | 68 |

| QJH-40WL | M60X2 | 162 | 36 | 50 | 24 | 1.97 | 90 | 80 |

| (Female thread connnection dimensions) | ||||||

| Model | DM | L | D1 | L3 | H | B |

| QJH-6WL | M16X1.5 | 68 | 6 | 10 | 27 | 24 |

| QJH-10WL | M18X1.5 | 76 | 10 | 14 | 37 | 34 |

| QJH-15WL | M27X1.5 | 88 | 15 | 16 | 46 | 44 |

| QJH-20WL | M33X2 | 102 | 18 | 16 | 55 | 48 |

| QJH-25WL | M42X2 | 116 | 22 | 20 | 61 | 58 |

| QJH-32WL | M48X2 | 129 | 30 | 20 | 72 | 68 |

| QJH-40WL | M60X2 | 147 | 36 | 24 | 90 | 80 |

| Model | L | L1 | H | H1 | ∮ | 2-∮2 | 2-∮1 | 4-M |

| QJH-10F | 103 | 127 | 58 | 36 | ∮68 | ∮22 | ∮10 | M10 |

| QJH-15F | 113.5 | 127 | 68 | 40 | ∮75 | ∮15 | ∮10 | M10 |

| QJH-20F | 117.4 | 184 | 72 | 42 | ∮78 | ∮30 | ∮20 | M10 |

| QJH-25F | 133.5 | 184 | 86 | 56 | ∮100 | ∮38 | ∮25 | M12 |

| QJH-32F | 145.4 | 215 | 103 | 62 | ∮110 | ∮45 | ∮32 | M12 |

| QJH-40F | 175 | 215 | 120 | 73 | ∮130 | ∮55 | ∮40 | M16 |

| QJH-50F | 190 | 229 | 128 | 86 | ∮150 | ∮60 | ∮48 | M18 |

| QJH-65F | 240 | 229 | 160 | 98 | ∮175 | ∮70 | ∮60 | M22 |

| Model | 2-D | L2 | L | L1 | H | H1 | F | E | N |

| QJH-50F | ∮62 | 17 | 200 | 30 | 110 | 74 | 118 | 55 | 250 |

| QJH-65F | ∮77 | 22 | 250 | 45 | 140 | 101.2 | 132 | 70 | 250 |

| QJH-80F | ∮91 | 25 | 265 | 45 | 150 | 113.1 | 142 | 75 | 315 |

A high-pressure ball valve is a type of valve designed to handle high-pressure applications. It is commonly used in industries such as oil and gas, chemical processing, power generation, and hydraulic systems.

The ball valve consists of a hollow ball with a hole (or bore) through the center. When the valve is in the closed position, the hole is perpendicular to the flow, blocking the passage of fluid. When the valve is in the open position, the hole aligns with the flow, allowing fluid to pass through.

High-pressure ball valves are specifically designed to withstand the high pressures and temperatures typically found in industrial applications. They are constructed using materials such as stainless steel, carbon steel, or other alloys that can handle the pressure and resist corrosion.

Some key features of high-pressure ball valves include:

Pressure rating: High-pressure ball valves are designed to handle pressures ranging from several hundred to several thousand PSI (pounds per square inch).

Full bore or reduced bore: Full bore ball valves have a larger hole size, allowing for maximum flow capacity. Reduced bore ball valves have a smaller hole size, which can restrict flow but may offer cost savings.

Floating or trunnion-mounted ball: Floating ball valves have the ball supported by two valve seats, allowing it to float and move with the flow. Trunnion-mounted ball valves have the ball supported by trunnions, which reduces friction and wear, making them suitable for higher pressures.

Seal options: High-pressure ball valves may use various sealing mechanisms, such as O-rings, PTFE (polytetrafluoroethylene) seats, or metal-to-metal seals, to ensure leak-tight operation.

Actuation options: High-pressure ball valves can be manually operated with a handle or lever, or they can be automated using pneumatic, electric, or hydraulic actuators for remote operation.

It is important to select a high-pressure ball valve that meets the specific requirements of the application, including pressure rating, temperature range, flow capacity, and compatibility with the fluid being handled. Proper installation, maintenance, and periodic inspection are also necessary to ensure the valve's reliable and safe operation.

Company Profile:

FENGHUA KAIYANG ELECTROMECHANICAL CO.,LTD. specailly manufacturer and market hydraulic ball valve,hydraulic fitting,pneumatic control element,air source units,pneumatic execute element and pneumatic assistant element.We have passed ISO9001:2000 quality system authentication.With advanced technology and equipment,good quality,our products sale far to many countries.In order to meet more and more customer's requirements.

We always stick to the enterprise spirit"Quality First,Good Serivice,Mutal Benefi