|

NINGBO DELY AUTOMATION Co.,Ltd.

|

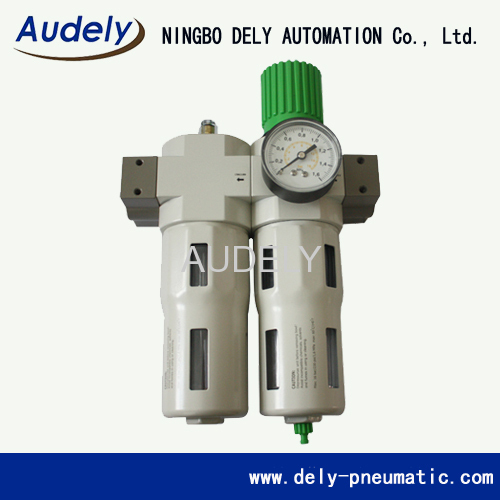

FESTO OU air filter regulator+lubricator

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Festo type FRL, OU consisted OFR and OL, each unit can be ordered separated. it cleans the fluid oil, condensation and dirt from compressored air

Product name: OU filter regulater+lubricator Order code:

Order code:

| OU | G1/4 | MINI | |||

| spec. | size | press. | Grade of filtration | SIZE | DRAIN |

| filter, regulator, lubricator | G1/8, G1/4, G3/8, G1/2, G3/4, G1 | blank:0.5~1.2MPa; 7: 0.5~7bar | blank: 40µm; 5m:5µm | MINI; MIDI; MAXI | Blank:manual;S:semi-automatic; A:automatic |

the regulator color: YELLOW, GREEN

thread: BSPT, BSP, NPT and so on

new type: OU, M5, (working pressure: 0~10bar)

OU filter regulater+lubricator

Introduction

The OU consisted of OFR and OL,each unit can be ordered separately.

The OF with water separator clean the compressed air of fluid oil,condensation and dirt.Particles.For special application,the standard 40μm filter element may easily be replaced by a 5μm filter element.

The OR maintain imputting constant operating pressure despite fluctuation in line pressure and the amount of air consumed.The proportional lubricator adds a regulated quantity of oil to the filtered air.The oil-mist content proportional to the flow and oil can be added during operation.The oil drip rate is controiled by the adjustable bolt.Normally,1 to 12 drops/1000L of the air is Suffcient.

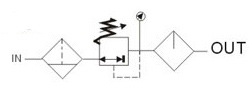

Symbol

Ordering Code

| OU | 1/4 | * | * | MINI | * |

| | | | | | | | | | | | |

| Model | Connection | Grade of filtration | Manomter | Size | Drain way |

| 1/8 1/4 3/8 1/2 3/4 1 | Blank:40μm 5M:5μm | Blank:12bar 7:7bar | MINI MIDI MAXI | Blank:Manual condensate drain | |

| A:Automatic condensate drain |

Specification

| Service units | MINI | MIDI | MAXI | ||||||

| Manual condensate drain | Working pressure: 12bar,40μm | OU-1/8-MINI | OU-1/4-MINI | OU-3/8-MINI | OU-3/8-MIDI | OU-1/2-MIDI | OU-3/4-MIDI | OU3/4-MAXI | OU-1-MAXI |

| Working pressure: 7bar,40μm | OU-1/8-7-MINI | OU-1/4-D-7-MINI | OU-3/8-7-MINI | OU-3/8-7-MIDI | OU-1/2-7-MIDI | OU-3/4-7-MIDI | OU-3/4-7-MAXI | OU-1-7-MAXI | |

| Working pressure: 12bar,5μm | OU-1/8-5M-MINI | OU-1/4-5M-MINI | OU-3/8-5M-MINI | OU-3/8-5M-MIDI | OU-1/2-5M-MIDI | OU-3/4-5M-MIDI | OU-3/4-5,-MAXI | OU-1-5M-MAXI | |

| Automatic condensate drain | Working pressure: 12bar,40μm | OU-1/8-MINI-A | OU-1/4-MINI-A | OU-3/8-MINI-A | OU-3/8-MIDI-A | OU-1/2-MIDI-A | OU-3/4-MIDI-A | OU-3/4-MAXI-A | OU-1-MAXI-A |

| Working pressure: 7bar,40μm | OU-1/8-7-MINI-A | OU-1/4-D-7-MINI-A | OU-3/8-7-MINI-A | OU-3/8-7-MIDI-A | OU-1/2-7-MIDI-A | OU-3/4-7-MIDI-A | OU-3/4-7-MAXI-A | OU-1-7-MAXI-A | |

| Working pressure: 12bar,5μm | OU-1/8-5M-MINI-A | OU-1/4-5M-MINI-A | OU-3/8-5M-MINI-A | OU-3/8-5M-MIDI-A | OU-1/2-5M-MIDI-A | OU-3/4-5M-MIDI-A | OU-3/4-5M-MAXI-A | OU-1-5M-MAXI-A | |

| Manometer | 0~12bar | OMA-40-16-1/8 | OMA-50-16-1/4 | ||||||

| 0~7bar | OMA-40-10-1/8 | OMA-50-10-1/4 | |||||||

| Medium | Compressed Air | ||||||||

| Features of structure | Sintered filter with water sparator;MINI/MIDI:Diaphragm type regulator;MAX:Piston type regulator Direct connstat-density lubricator | ||||||||

| Mounting type | Pipe mounting or foot mounting | ||||||||

| Assembly position | Vertical ±5° | ||||||||

| Connection | G1/8 | G1/4 | G3/8 | G3/8 | G1/2 | G3/4 | G3/4 | G1 | |

| Standard nominal flow rate | OU-…(-A) | 700 | 1000 | 1200 | 2000 | 2600 | 2600 | 7000 | 8000 |

| OU-…-7-(-A) | 800 | 1300 | 1500 | 2500 | 2800 | 2800 | 8500 | 8700 | |

| OU-…-5M-(-A) | 600 | 850 | 1050 | 1700 | 1800 | 2100 | 6500 | 7200 | |

| Primary pressure | Manual condensate drain | 1~16bar | |||||||

| Automatic condensate drain | 1.5~12bar | ||||||||

| Working pressure | 0.5~12bar/0.5~7bar | ||||||||

| Min.Standard nominal flow rate | 31/min | 61/min | 101/min | ||||||

| Grade of filtration | 40μm/5μm | ||||||||

| Capacity of condensate fluid | 22ml | ||||||||

| Temperature range | 0~60℃ | ||||||||

| Materials information | Housing:Zinc die-casting;Filter bowl/oil bowl:PC;Metal bowl guard:Aluminium alloy;Sealing:NBR;Adjusting knob:Pom | ||||||||

Overall Dimensions

| Model | E1 | E2 | E3 | E4 | E5 | E6 | E7 | F1 | F2 |

| OU-…-MINI | 104 | 92 | 40 | 39 | 76 | 95 | 2 | G1/8/G1/4/G3/8 | M36X1.5 |

| OU-…-MIDI | 160 | 125 | 55 | 47 | 93 | 112 | 3 | G1/8/G1/2/G3/4 | M52X1.5 |

| OU-…-MAXI | 162/182 | 146/157 | 66 | 53 | 104 | 124 | 3 | G3/4/G1 | M36X1.5 |

| Model | F3Φ | F4 | F5Φ | F6Φ | L1 | L2 | L3 | H1 | H2 | H3 | H4 | H5 | H6 |

| OU-…-MINI | 31 | M4 | 4.5 | 40 | 44 | 35 | 11 | 194 | 169 | 69 | 17.5 | 20 | 15 |

| OU-…-MIDI | 50 | M5 | 5.5 | 52 | 71 | 60 | 22 | 250 | 206 | 97 | 24.5 | 32 | 15 |

| OU-…-MAXI | 31 | M5 | 5.5 | 63 | 71 | 60 | 22 | 252 | 223 | 80 | 24.5 | 32/40 | 15 |

FESTO type

A pneumatic filter regulator is a device used in pneumatic systems to filter and regulate the pressure of compressed air. It combines the functions of a filter and a regulator into a single unit.

The filter component of the pneumatic filter regulator removes impurities such as dust, dirt, and water from the compressed air. This helps to protect downstream components, such as valves and actuators, from damage and ensures the air is clean and free from contaminants.

The regulator component of the pneumatic filter regulator controls the pressure of the compressed air. It maintains a consistent and accurate pressure level, ensuring that the pneumatic system operates efficiently and reliably. The regulator can be adjusted to set the desired pressure level and can compensate for fluctuations in the air supply.

Pneumatic filter regulators are commonly used in various industries, including manufacturing, automation, and automotive. They are typically installed near the point of use, such as at the entry point of a machine or equipment, to ensure that the air being used is clean and at the correct pressure.

Different pneumatic filter regulators may have various features and specifications, such as different pressure ranges, flow rates, and filtration levels. Some models may also include additional features like pressure gauges, pressure relief valves, or automatic drain valves to further enhance their functionality.

Overall, pneumatic filter regulators play a crucial role in maintaining the performance and reliability of pneumatic systems by ensuring clean and regulated compressed air supply.

Company Profile:

Ningbo Dely Automation CO.,LTD. specailly manufacturer and market hydraulic ball valve,hydraulic fitting,pneumatic control element,air source units,pneumatic execute element and pneumatic assistant element.We have passed ISO9001:2000 quality system authentication.With advanced technology and equipment,good quality,our products sale far to many countries.In order to meet more and more customer's requirements.

We always stick to the enterprise spirit"Quality First,Good Serivice,Mutal Benefit"